Water Jet Cutter Filters

We stock a range of filters and filter housings ideal for protecting water jet cutters from damage and improving performance.

Please browse our range below and get in touch if you have any questions. You can also learn more about the filtration solutions for jet cutters by reading the information at the bottom of this page.

Showing all 29 results

-

1025GD Graded Depth Protection 10″ Sediment Filters

1025GD Graded depth sediment filters are premium grade Poly-spun polypropylene sediment filters. These filters will give you extra protection from sediment with their gradual depth layers of filtration. Course sediment is trapped… View ArticlePrice range: $12.75 through $14.30 Select options This product has multiple variants. The options may be chosen on the product page1025GD Graded Depth Protection 10″ Sediment Filters

1025GD Graded depth sediment filters are premium grade Poly-spun polypropylene sediment filters. These filters will give you extra protection from sediment with their gradual depth layers of filtration. Course sediment is trapped… View Article -

1025PW1Abs Pleated Washable 1 Micron Absolute 9 3/4″ x 2.5″ Filter

1025PW1Abs 1 micron Absolute rated pleated washable beer, wine & water filter. Beer filter ideal for fine filtration where you need to be able to wash the filter out. Depending… View Article1025PW1Abs Pleated Washable 1 Micron Absolute 9 3/4″ x 2.5″ Filter

1025PW1Abs 1 micron Absolute rated pleated washable beer, wine & water filter. Beer filter ideal for fine filtration where you need to be able to wash the filter out. Depending… View Article -

10″ Absolute Rated Pleated Filters Double Open End

10″ Absolute rated DOE pleated polypropylene filters. Double Open End Filter with a sealing washer at each end of the filter. Used to produce high quality water, also used in wine & beer… View ArticlePrice range: $71.95 through $87.20 Select options This product has multiple variants. The options may be chosen on the product page10″ Absolute Rated Pleated Filters Double Open End

10″ Absolute rated DOE pleated polypropylene filters. Double Open End Filter with a sealing washer at each end of the filter. Used to produce high quality water, also used in wine & beer… View Article -

Sale!

KDFSALE!

AP1025KDF/GAC 10″ KDF and Silver Impregnated Carbon Filter

High Flow 10″ KDF and Silver Impregnated Granular Coconut Carbon Water Filter ideal for Under Sink Water Filter Systems and Point of Entry Caravans / RV filter systems.

AP1025KDF/GAC 10″ KDF and Silver Impregnated Carbon Filter

High Flow 10″ KDF and Silver Impregnated Granular Coconut Carbon Water Filter ideal for Under Sink Water Filter Systems and Point of Entry Caravans / RV filter systems.

-

Single QMP 10″ Filter Housing with 3/4″ Bsp Ports

QMP White housing with 3/4″ female BSP inlet and outlet. These housings will take most 10″ x 2.5″ filter cartridges. Maximum pressure 900kpa (125psi) Cold water use only. Mounting bracket and… View ArticlePrice range: $58.00 through $73.00 Select options This product has multiple variants. The options may be chosen on the product pageSingle QMP 10″ Filter Housing with 3/4″ Bsp Ports

QMP White housing with 3/4″ female BSP inlet and outlet. These housings will take most 10″ x 2.5″ filter cartridges. Maximum pressure 900kpa (125psi) Cold water use only. Mounting bracket and… View Article -

Twin QMP 10″ Filter Housing with 3/4″ Bsp outlets and Spanner S/S Bracket

American made Heavy Duty internal or external twin 10″ water filter housings with 3/4″ BSP portsTwin QMP 10″ Filter Housing with 3/4″ Bsp outlets and Spanner S/S Bracket

American made Heavy Duty internal or external twin 10″ water filter housings with 3/4″ BSP ports -

Triple QMP 10″ Filter Housing with 3/4″ BSP outlets and Spanner White Bracket

Heavy Duty internal or external twin 10″ filter housings with 3/4″ BSP ports This quality USA Made housing system with give you years of trouble free filtration, suitable for residential or… View ArticleTriple QMP 10″ Filter Housing with 3/4″ BSP outlets and Spanner White Bracket

Heavy Duty internal or external twin 10″ filter housings with 3/4″ BSP ports This quality USA Made housing system with give you years of trouble free filtration, suitable for residential or… View Article -

316 Stainless Steel Filter Housing suits 10″ x 2.5″ Filters

316 Stainless Steel Housing 10″ standard available in 3/4″ or 1″ Bsp ports. This housing will take all 10″ x 2.5″ standard water filter cartridges. Heavy duty S/S housing ideal… View Article$299.80 Select options This product has multiple variants. The options may be chosen on the product page316 Stainless Steel Filter Housing suits 10″ x 2.5″ Filters

316 Stainless Steel Housing 10″ standard available in 3/4″ or 1″ Bsp ports. This housing will take all 10″ x 2.5″ standard water filter cartridges. Heavy duty S/S housing ideal… View Article -

NEW!

304 Stainless Steel Water Filter Housing 1/2″ Ports Suits 10″ x 2.5″ Filters

304 Stainless Steel 10″ Housing with 1/2″ Bsp ports Includes bracket & opening wrench. Suitable for 10″ x 2.5″ Water Filters.

304 Stainless Steel Water Filter Housing 1/2″ Ports Suits 10″ x 2.5″ Filters

304 Stainless Steel 10″ Housing with 1/2″ Bsp ports Includes bracket & opening wrench. Suitable for 10″ x 2.5″ Water Filters.

-

2025PS Sediment Poly-spun Water Filter 20″ x 2.5″

2025PS Poly-spun Sediment Filter 20″ x 2.5″. Reduces Dirt, Rust, Algae and Suspended Sediment. These filters fit all standard 20″ filter housings. EC210 EV9534-26 5 Micron, Moffit RW0027 Dimensions are… View Article$16.20 Select options This product has multiple variants. The options may be chosen on the product page2025PS Sediment Poly-spun Water Filter 20″ x 2.5″

2025PS Poly-spun Sediment Filter 20″ x 2.5″. Reduces Dirt, Rust, Algae and Suspended Sediment. These filters fit all standard 20″ filter housings. EC210 EV9534-26 5 Micron, Moffit RW0027 Dimensions are… View Article -

20″ Graded Depth Sediment Filters 2025GD

2025GD Graded depth sediment filters are premium grade Poly-spun polypropylene sediment filters. These filters will give you extra protection from sediment with their gradual depth layers of filtration. Course sediment is trapped… View ArticlePrice range: $23.60 through $26.20 Select options This product has multiple variants. The options may be chosen on the product page20″ Graded Depth Sediment Filters 2025GD

2025GD Graded depth sediment filters are premium grade Poly-spun polypropylene sediment filters. These filters will give you extra protection from sediment with their gradual depth layers of filtration. Course sediment is trapped… View Article -

Sale!

SALE!

20″ x 2.5″ 1 and 5 Micron Nominal PP Pleated Filters Double Open End

Double Open End Filter with a sealing washer at each end of the filter. 1 Micron and 5 micron pleated PP polypropylene 20″ x 2.5″ filters. Nominal rated filters for a better… View ArticlePrice range: $55.00 through $125.40 Select options This product has multiple variants. The options may be chosen on the product page20″ x 2.5″ 1 and 5 Micron Nominal PP Pleated Filters Double Open End

Double Open End Filter with a sealing washer at each end of the filter. 1 Micron and 5 micron pleated PP polypropylene 20″ x 2.5″ filters. Nominal rated filters for a better… View Article -

Unicel Pleated Washable Sediment Filter for 20″ x 4.5″ Filter Housings

1 Micron, 5 Micron, 10 Micron, & 50 Micron 2045PW Pleated Washable 20 inch x 4.5 inch Polyester Sediment Filter. The white cap Unicel filters are a premium USA-made product…. View ArticlePrice range: $97.30 through $182.00 Select options This product has multiple variants. The options may be chosen on the product pageUnicel Pleated Washable Sediment Filter for 20″ x 4.5″ Filter Housings

1 Micron, 5 Micron, 10 Micron, & 50 Micron 2045PW Pleated Washable 20 inch x 4.5 inch Polyester Sediment Filter. The white cap Unicel filters are a premium USA-made product…. View Article -

Clear 20″ x 4.5″ Filter Housing

20” x 4.5″ Clear Jumbo Filter Housing. Large housing will take most 20″ x 4.5″ filter cartridges. FDA grade materials, Polypropylene head cap, Acrylic clear sump. It is recommended to have a… View ArticlePrice range: $172.00 through $284.50 Select options This product has multiple variants. The options may be chosen on the product pageClear 20″ x 4.5″ Filter Housing

20” x 4.5″ Clear Jumbo Filter Housing. Large housing will take most 20″ x 4.5″ filter cartridges. FDA grade materials, Polypropylene head cap, Acrylic clear sump. It is recommended to have a… View Article -

20″ x 4.5″ 304 and 316 Stainless Steel Filter Housing Kits

20 inch Jumbo Stainless Steel filter housing 1″ Bsp inlet & outlets suits 20″ x 4.5″ filters. Ideal for where a high flow rate is required eg. house, rural or commercial applications…. View ArticlePrice range: $519.50 through $895.00 Select options This product has multiple variants. The options may be chosen on the product page20″ x 4.5″ 304 and 316 Stainless Steel Filter Housing Kits

20 inch Jumbo Stainless Steel filter housing 1″ Bsp inlet & outlets suits 20″ x 4.5″ filters. Ideal for where a high flow rate is required eg. house, rural or commercial applications…. View Article -

20″ Big Blue Twin Large High Flow Rate Housing System

Twin Large 20″ System filter housing 1″ Bsp inlet & outlets (3/4″ with bush). Suits 20″ x 4.5″ filters Ideal for Whole of house, Pumps, Tanks etc. or any where… View ArticlePrice range: $347.00 through $407.00 Select options This product has multiple variants. The options may be chosen on the product page20″ Big Blue Twin Large High Flow Rate Housing System

Twin Large 20″ System filter housing 1″ Bsp inlet & outlets (3/4″ with bush). Suits 20″ x 4.5″ filters Ideal for Whole of house, Pumps, Tanks etc. or any where… View Article -

20″ Big Blue Twin Large High Flow Rate Housing System with Gauges

Twin Large 20″ System filter housing 1″ Bsp inlet & outlets suits 20″ x 4.5″ filters Ideal for Whole of house, Pumps, Tanks etc. or any where a high flow… View ArticlePrice range: $413.00 through $473.00 Select options This product has multiple variants. The options may be chosen on the product page20″ Big Blue Twin Large High Flow Rate Housing System with Gauges

Twin Large 20″ System filter housing 1″ Bsp inlet & outlets suits 20″ x 4.5″ filters Ideal for Whole of house, Pumps, Tanks etc. or any where a high flow… View Article -

Pentek Size 2 Bag Filter Housing 304 SS

Pentek Size No2 High Flow Bag Filter Housing. SSBFH-2-304-2BSP 2mm thick 304 SS Electro Polished Finish. 30,000 litre per hour depending on bag micron rating and water quality. Quality construction… View ArticlePentek Size 2 Bag Filter Housing 304 SS

Pentek Size No2 High Flow Bag Filter Housing. SSBFH-2-304-2BSP 2mm thick 304 SS Electro Polished Finish. 30,000 litre per hour depending on bag micron rating and water quality. Quality construction… View Article -

Size No2 Polypropylene Felt Filter Bags PE2

Size number 2 filter bags. Polypropylene Felt with a Stainless Steel ring. Handle for ease of installation and removal. These size 2 filter bags will fit all industry-standard Size No2 bag housings…. View Article$26.00 Select options This product has multiple variants. The options may be chosen on the product pageSize No2 Polypropylene Felt Filter Bags PE2

Size number 2 filter bags. Polypropylene Felt with a Stainless Steel ring. Handle for ease of installation and removal. These size 2 filter bags will fit all industry-standard Size No2 bag housings…. View Article -

Size 2 Nylon Mesh Filter Bags

Size 2 nylon mesh filter bags suitable to use in all size 2 bag housings. Nylon Monofilament Mesh Filter Bag polyester thread and collar support. Available with S/S Stainless Steel or… View Article$32.70 Select options This product has multiple variants. The options may be chosen on the product pageSize 2 Nylon Mesh Filter Bags

Size 2 nylon mesh filter bags suitable to use in all size 2 bag housings. Nylon Monofilament Mesh Filter Bag polyester thread and collar support. Available with S/S Stainless Steel or… View Article -

Pentek 150356 PBH-420 BB Bag Filter Housing Kit

The Pentek 150356 PBH-420 1-1/2″ Bsp inlet and outlets. Suitable residential, commercial, and industrial applications. The sump, cap, basket, vent plug, and drain plug are made of polypropylene for strength… View ArticlePrice range: $126.25 through $570.00 Select options This product has multiple variants. The options may be chosen on the product pagePentek 150356 PBH-420 BB Bag Filter Housing Kit

The Pentek 150356 PBH-420 1-1/2″ Bsp inlet and outlets. Suitable residential, commercial, and industrial applications. The sump, cap, basket, vent plug, and drain plug are made of polypropylene for strength… View Article -

Pentair BP-420-25 micron Bag Filter to suit 20 inch BB Bag Housings PBH-420

25 MICRON BAG FILTERS Part Number BP-420-25, 155390-03 Suits 20″ Pentek Pentair Big Blue Bag Filter Housings only (PBH-420-1 and PBH-420-1.5). Filter rated at 25 micron Length – 457mm width… View ArticlePentair BP-420-25 micron Bag Filter to suit 20 inch BB Bag Housings PBH-420

25 MICRON BAG FILTERS Part Number BP-420-25, 155390-03 Suits 20″ Pentek Pentair Big Blue Bag Filter Housings only (PBH-420-1 and PBH-420-1.5). Filter rated at 25 micron Length – 457mm width… View Article -

CWF-X100 Bag Filter Housing and Pall 416669B FSI X100

PALL FSI X100 Compatible Size 5 Replacement Housings, Baskets, and Gaskets.

Price range: $29.80 through $898.00 Select options This product has multiple variants. The options may be chosen on the product pageCWF-X100 Bag Filter Housing and Pall 416669B FSI X100

PALL FSI X100 Compatible Size 5 Replacement Housings, Baskets, and Gaskets.

-

Bag Filter to Suit X100 Filter Housings

BAG FILTERS to Suit X100 Housings. Part Numbers: 1 micron – BPONG1X01 5 micron – BPONG5X01 10 micron – BPong10X01 25 micron – BPONG25X01 50 micron – BPONG50X01 100 micron… View Article$21.00 Select options This product has multiple variants. The options may be chosen on the product pageBag Filter to Suit X100 Filter Housings

BAG FILTERS to Suit X100 Housings. Part Numbers: 1 micron – BPONG1X01 5 micron – BPONG5X01 10 micron – BPong10X01 25 micron – BPONG25X01 50 micron – BPONG50X01 100 micron… View Article -

Clear Pentek 10″ 3/4″ BSP Housing 150096

Pentek 150096 10″ Clear Housing 3/4″ BSP Ports. Replaces the Pentek 150106 housings. Clear sump made of Styrene Acrylonitrile long lasting, non crazing, high quality material. Dimensions: 321mm x 133mm… View ArticlePrice range: $118.00 through $135.00 Select options This product has multiple variants. The options may be chosen on the product pageClear Pentek 10″ 3/4″ BSP Housing 150096

Pentek 150096 10″ Clear Housing 3/4″ BSP Ports. Replaces the Pentek 150106 housings. Clear sump made of Styrene Acrylonitrile long lasting, non crazing, high quality material. Dimensions: 321mm x 133mm… View Article -

20″ x 2.5″ 3M™ Micro-Klean™ RT Series Sediment Filter 5 micron

Genuine 20″ x 2.5″ 3M™ Micro-Klean™ RT Series Sediment Filter – 5 micron. RT Series RT20B16NN 3M ID AK200025307. 20″ graded depth polyspun filter ideal for particulate reduction. Dramatically reduces… View Article20″ x 2.5″ 3M™ Micro-Klean™ RT Series Sediment Filter 5 micron

Genuine 20″ x 2.5″ 3M™ Micro-Klean™ RT Series Sediment Filter – 5 micron. RT Series RT20B16NN 3M ID AK200025307. 20″ graded depth polyspun filter ideal for particulate reduction. Dramatically reduces… View Article -

NEW!

Parker Fulflo Ecobond and Durabond Sediment Filters 20″ and 19.5″

Genuine Parker Fulfo Ecobond and Durabond Sediment Filters. High-quality American-made Double Open Ended filters in 20″ x 2.5″ and 19.5″ x 2.5″ sizes.$48.00 Select options This product has multiple variants. The options may be chosen on the product pageParker Fulflo Ecobond and Durabond Sediment Filters 20″ and 19.5″

Genuine Parker Fulfo Ecobond and Durabond Sediment Filters. High-quality American-made Double Open Ended filters in 20″ x 2.5″ and 19.5″ x 2.5″ sizes. -

NEW!

20″ x 4.5″ Big Black Twin Stage High Flow Water Filter Housing

20″ x 4.5″ Big Black Twin Stage High Flow Water Filter Housing with Black UV Resistant Sumps for residential and commercial applicationsPrice range: $405.00 through $465.00 Select options This product has multiple variants. The options may be chosen on the product page20″ x 4.5″ Big Black Twin Stage High Flow Water Filter Housing

20″ x 4.5″ Big Black Twin Stage High Flow Water Filter Housing with Black UV Resistant Sumps for residential and commercial applications -

NEW!

Twin QMP 10″ Filter Housing with 3/4″ BSP Brass Ports and Spanner S/S Bracket

American made Heavy Duty internal or external twin 10″ water filter housings with 3/4″ BSP ports

Twin QMP 10″ Filter Housing with 3/4″ BSP Brass Ports and Spanner S/S Bracket

American made Heavy Duty internal or external twin 10″ water filter housings with 3/4″ BSP ports

Water Jet Cutter Filters

Clarence Water Filters is one of Australia’s leading suppliers of water filters. We stock a wide range of products including filters and filter housings ideal for protecting water jet cutters.

If you need assistance choosing the right products, contact us today. We’ll look at your water quality and the requirements of your jet cutter to find an appropriate solution.

Contaminants Which Can Damage Water Jet Cutters

Sediment

Sediment particles can quickly clog up the nozzles on a water jet cutter head and can cause abrasive damage to internal components.

The presence of sand, rust, dirt, and metal particles can also ruin the materials that are being cut.

Fortunately, sediment is easy to deal with. It will require a series of 4-6 sediment filters with increasingly fine micron ratings. Most jet cutters will start with 25 micron filters then work their way down to 1 micron Absolute filters for the final stage.

If extremely clean water is required for a specific material or manufacturing process, reverse osmosis can be used to remove virtually all sediment particles.

TDS and Hardness

Total Dissolved Solids refers to all dissolved organic and inorganic particles including minerals, salts, metals, cations, and anions which can be found in water. Imbalanced TDS levels can cause corrosion and abrasion of metal components.

Hardness specifically refers to dissolved calcium and magnesium salts in water, usually in the form of bicarbonates, chlorides, and sulphates. Carbonate hardness can cause scale formation and high levels of salt can cause corrosion or pitting of stainless steel.

Reverse osmosis membranes and systems using ion exchange resin are the best approaches for reducing TDS and hardness. Contact us to discuss the best option for your jet cutter, based on your water quality.

Chemicals

High level chemical content can eventually have a corrosive effect on metal components and rubber seals. Fortunately, most chemicals can easily be removed using carbon filtration.

Water Jet Cutter Filtration Solutions

A number of approaches can be used to improve your process water and deal with waste water.

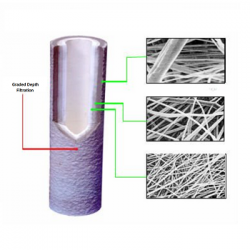

Mechanical Filtration (Sediment Filtration)

Mechanical filters act like a sieve, trapping particulate contaminants before they can damage your jet cutter’s head or internal components.

Most waterjet cutters will require several sediment filters for process water, with each filter finer than the last. The goal being to remove any particulates which can damage the jet cutter.

Mechanical filtration is also useful for cleaning up waste water. Businesses usually have strict rules regarding the quality of water they can dispose of in drains, so they must remove the bulk of particles using

There are several types of mechanical filters available including pleated washable filters, disposable polyspun filters, ultra-fine polypropylene cage filters, and polyspun filters.

Carbon Filtration (Chemical filtration)

Carbon can adsorb chemical contaminants including volatile organic compounds, chlorine, and petrochemicals. Compressed carbon blocks are also capable of capturing sediment particles and heavy metals.

Ion Exchange (TDS and Hardness Filtration)

Ion exchange resin consists of plastic polymer beads which have been charged with a molecule that has a positive or negative charge. As water flows through the beads, contaminant ions are exchanged for the ions in the beads. It is a fantastic way to remove TDS and the minerals which cause scale build-up.

Reverse Osmosis (TDS, Sediment and Hardness Filtration)

Reverse osmosis consists of a series of filters followed by a membrane. Pressure is applied to one side of the membrane, pushing the water through while separating ultra-fine contaminants including sediment, dissolved solids, and hardness causing minerals. Useful for when very pure water is required.

Need Help? Get In Touch Today!

If you’d like to learn more about waterjet cutter filtration, please contact us at sales@clarencewaterfilters.com.au or give us a call on 02 6646 8565.