Description

17″ x 9″ Spot Free Washing TDS Resin System with click on hose fittings and carbon pre-filter

The 179TDSPOH system is a Demineralizing Spotless Rinse Water Filter designed to reduce TDS – Totally Dissolved Solids.

Dissolved solids are primarily responsible for causing water spots on windows, vehicle paint jobs, and boats. Removing TDS with a spot free system will give you a pristine finished surface. It also protects against pitting on clear coat surfaces and paint work.

TDS water filter systems are primarily used by professional vehicles detailers and window cleaners. However, they are also ideal for keen car enthusiasts, boat owners, and homeowners with a lot of glass.

The TDS System will stop streaking and spots on the windows and duco caused by mineral residue from our water. This will save you time and money while leave you with spot free windows and vehicles every time.

Spot Free Washing System – Features

The 179TDSPOH TDS water filter system is 17″ x 9″ media vessel with click on hose fittings making it a portable unit.

The vessel is a 13.2 litre reinforced fiberglass tank with a 2.5″ threaded opening for easy refilling. It also features a Polyethylene inner shell.

This system can produce superior water compared to bottled grade Distilled Water and even Reverse-Osmosis water which both still have a TDS reading around 5ppm in the bottle. Making this ideal for refilling batteries in machinery and golf carts etc..

Spot Free Washing System – Filtration Process

Stage 1: Sediment and Chemical Filtration

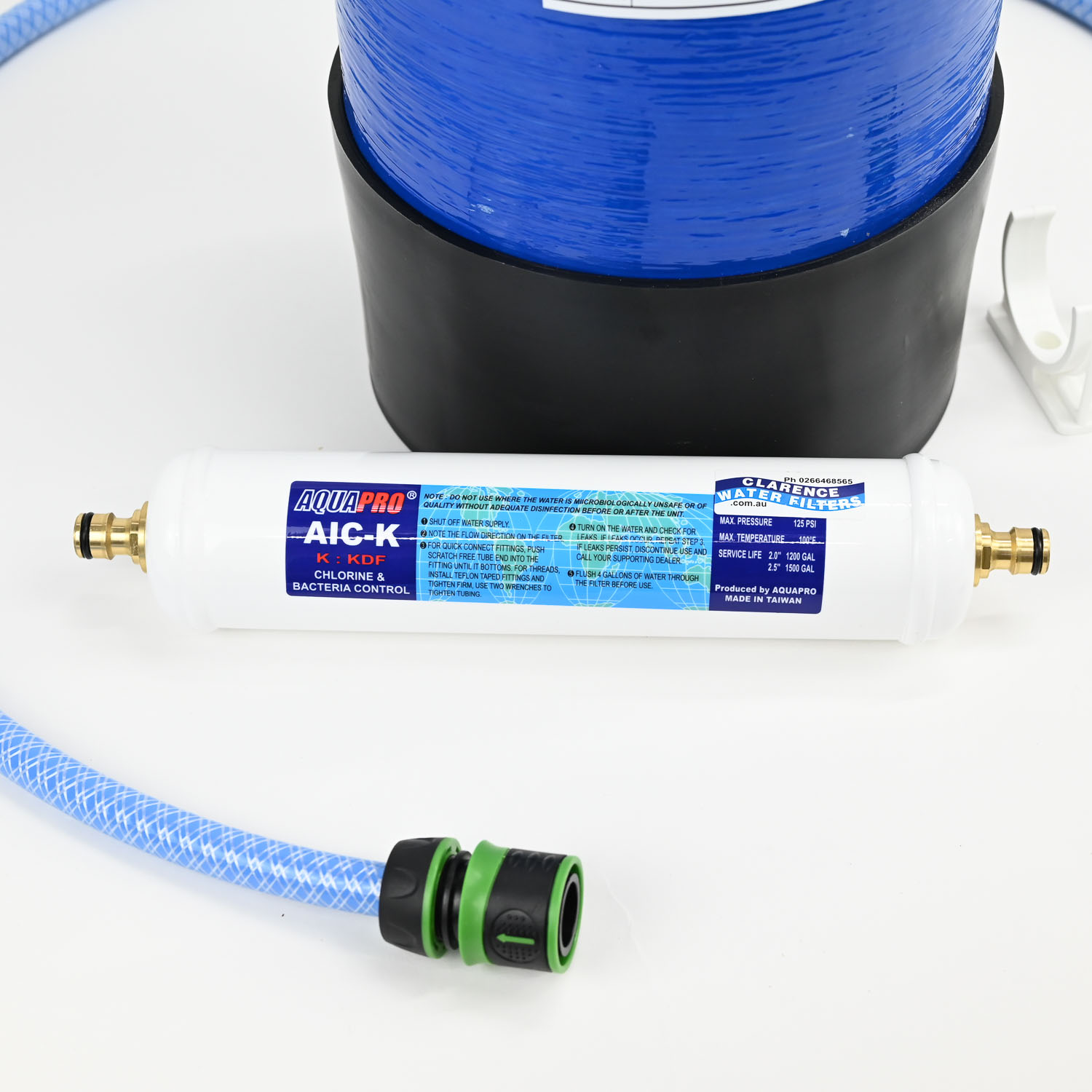

The first stage is an AIC-K inline carbon pre-filter containing KDF (Kinetic Degradation Fluxion) and GAC (Granular Activated Carbon). This 5 micron pre-filter reduces chlorine and chemicals that can shorten the life of the demineralizing resin.

Stage 2: Demineralising Ion Exchange Resin

The second stage is the resin vessel, where the water enters the inlet side and travels down through the resin and back up the centre tube to the outlet. The resin removes both positively and negatively charged dissolved solids from the water, exchanging them for harmless particles which will not damage or mark windows and painted surfaces.

The carbon pre-filter and resin vessel are fitted with standard brass click-on hose fittings making it portable and easy to connect to any garden hose.

Spot Free Washing System – What’s In The Box?

- AIC-K Carbon/KDF Water Filter (chemical and sediment removal) with 2 x Brass Push On Hose Fittings

- 17″ x 9″ Media Vessel with 2 x Brass click on hose fittings installed

- 12.5 Litres of MX-1 Mixed Bed Resin

- 2 x Plastic Garden Hose Fittings

- 1.5m of food grade 12mm hose included to connect the AIC-K carbon filter to the inlet of the resin vessel.

Additional 25 litre bags of Mixed bed resin are available in the product options.

Spot Free Washing System – Usage Tips

Any left over mixed bed resin must be stored out of the sun in a cold place in a air tight bag or container to stop it drying out until being used.

To extend the resin life use unfiltered water on the initial wet down and washing of dirty areas. Then switch over to the TDS free water for your final rinse.

When using a hose just a quick rinse running the TDS free water over entire the job will extend the life of the Demineralizing Resin.

To run the TDS free water over the average car should only take less then 2 minutes. If using a pressure clean as the final spot free rinse, we recommend using a small flow rate pressure cleaner to conserve water usage and extend the resin life.

For spot free rinse the resin is normally replaced when you get a reading of 8-10 ppm or higher or when spotting starts to appear depending on your application.

Remember that you only need a curtain of water to run over the job as a final rinse to achieve a spot free finish.

Always flush any new carbon filter before connecting to the resin system.

When refilling the resin, simply unscrew the top head and remove the head and drop tube as one then dump the old resin out and rinse the vessel out.

Add a couple of litres of water to the vessel then fill with new resin leaving room for the drop tube and screens. Push the drop tube and head down through the resin and screw the head down. Flush new resin before using.

- Capacity and service life of filters varies depending on water supply and how the system is used. as a guide the resin should be changed at 8-10 ppm TDS. The carbon pre filter should be changed every 12 months or 6000 Litres if not sooner.

- Dimensions are 490 mm high x 235 mm wide excluding hose fittings.

- System is designed as a portable unit with standard click on garden hose fittings of outdoors.

- If system is to be plumbed in, please consult with your plumber as the hose and fittings will need to be changed and a PLV pressure limiting valve up to 500 kpa installed.

- Larger systems are available on request.

It is recommended to run water through the resin system for a least 1 minute every few weeks just to keep the water in the system fresh. Keep away from heat or out of direct sunlight to reduce the temperature in the resin.

Specifications

- Maximum pressure rating 150 PSI

- Temperature range 1°-49° C

- Maximum Vacuum 127mmHg

This system is not to be used for Pneumatic or hyro-pneumatic applications.

Frequently Asked Questions

How long will the resin last?

The length of time your resin will last will depend on a number of factors and there is no defined volume in litres or time frame.

How hard or soft is the water that you’re running through your TDS system will determine the service life of the resin. Resin will last longer if you are in a soft water area up to 60 ppm compared to hard water areas above 140 ppm and if you are in extremely hard water areas you must use the TDS resin system sparingly to minimise resin change outs.

The bigger the system or vessel is the more resin it can hold, and the longer between change outs. The resin beads have a limit and capacity to attract contaminates, so when the resin is saturated it can no longer attract and has reached the end of its service life. This is why small volume single filter cartridges cannot handle the flow and have a very short service life.

Flow rate through the system should be set to the minimum to achieve the desired result for your application. If you used 20 LPM of water you will use up the capacity of the resin fast. It is recommended to reduce the flow as much as possible and try and keep the rinse down to less than 5 LPM to conserve the resin.

Interested in learning more about the benefits of spot free car washing systems?

Reviews

There are no reviews yet.